The stylish countertop water purifier turns drinking water into pure enjoyment.

Friends, have you ever faced these “drinking dilemmas”?

Want a cup of warm water? You have to boil it first, then wait for it to cool down… by the time it’s ready, you almost forgot that you were thirsty! Craving a good cup of tea? Tap water always carries that odd taste, and ruining the flavor... so you end up ordering coffee delivery instead. Rushing in the morning? Boil water, wait for it to cool, fill your bottle… by the time you’re done, you’re nearly late!

And then looking at the dusty kettle in the corner, the bulky water filter hogging space, and those giant bottled waters that take superhuman strength to lift… exhausting, right? If you’re someone who longs for a touch of refinement in life but also admits to being a little “lazy” at heart, then this is the perfect drinking solution:

It must be convenient—ideally “one step to everything.”

It shouldn’t take up space, but it should still look great.

Most importantly, it should make you feel safe to drink—and maybe even make you fall in love with drinking water!

Honestly, this PU-T01 countertop water purifier will open up a whole new world for you! No exaggeration—it can completely cure your “drinking procrastination” and turn the simple act of drinking water into a little daily joy.

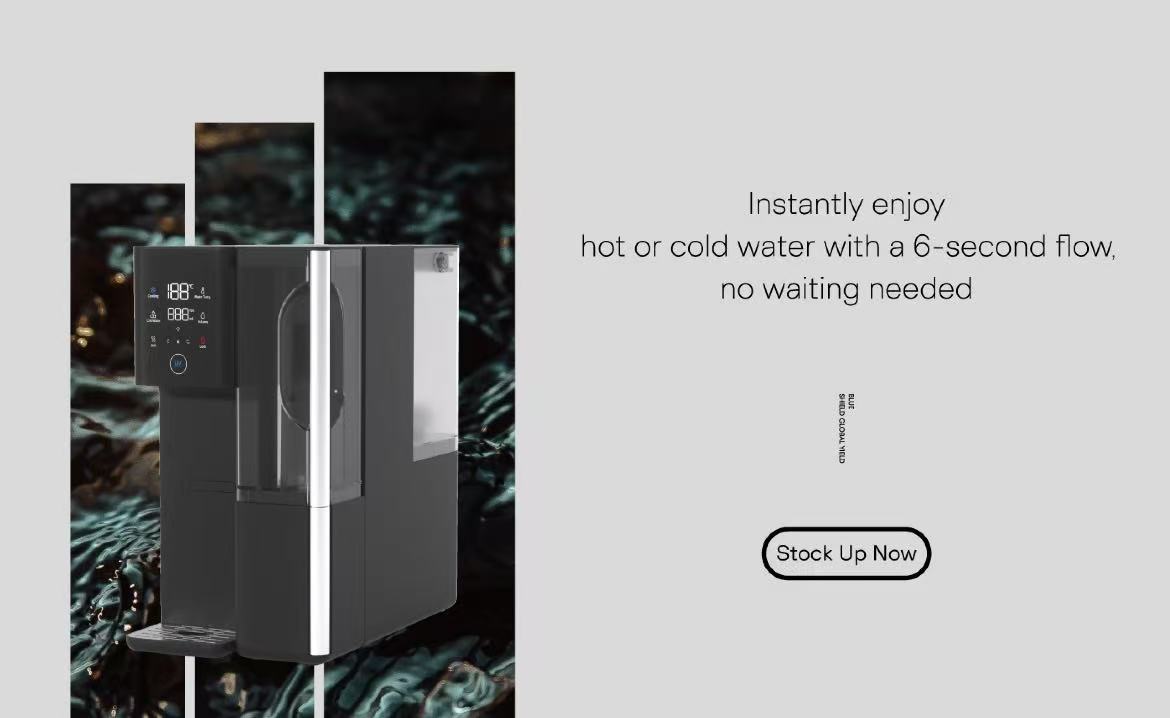

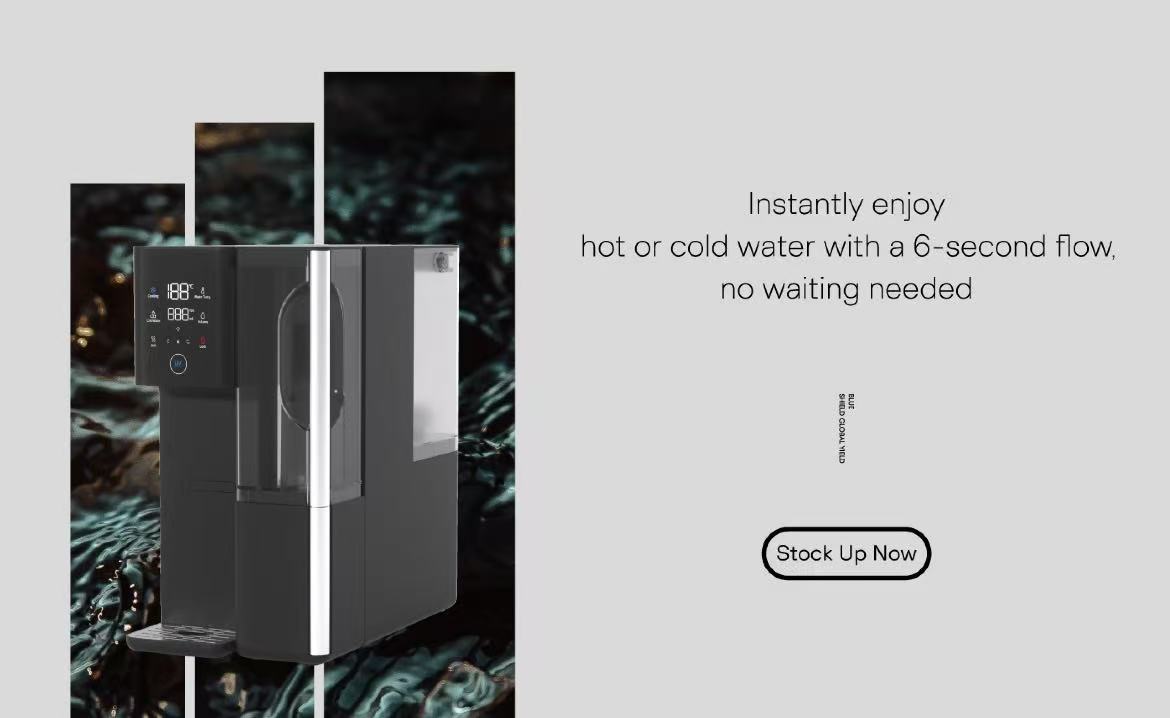

Lazy People Rejoice: Say Goodbye to Hassle—Drink Anytime You Want!

What makes the countertop water purifier irresistible is the “ultimate lazy-friendly” design!

No Installation—Plug & Play! Unbox it, find a spot on your counter (This countertop water filter is super compact), plug it in, fill the tank with tap water (Municipal water is sufficient.). Done! The whole setup takes less than 5 minutes. Forget about drilling, plumbing, or waiting for technicians. Whether you’re renting, renovating, or just hate trouble... Don’t afraid, your saver is coming!

Water in 3 Second, No More Waiting! Feeling thirsty? Walk up, press the button on the countertop water dispenser, and in just 3 seconds—you’ve got fresh purified water in your cup. Want warm water? You can also choose from multiple temperature options ( like 45°C for baby formula or 85°C for tea). Still instant! This hot and cold water dispenser let you to get rid of staring at a boiling kettle or waiting for water to cool. This sense of “instant gratification”, you have to experience it yourself!

One-Touch Control—Easy to Understand! The panel of the countertop water dispenser is simple and intuitive, with a thoughtful child-lock feature for families with kids. Changing the filter cartridge? Just a few easy steps, no fuss.

Time Saved = Time Enjoyed. All that time you used to waste boiling, waiting for cooling, and lugging water bottles can be saved. Now you can binge a show, do your makeup, or simply daydream. The countertop water dispenser help you achieve lazy living with value!

Style Meets Substance: A Chic Must Have for Every Home!

Convenience alone isn’t enough—for those who care about quality of life, appearances matter too! And the PU-T01 Countertop Water Purifier is truly where style meets performance.

Beautiful design: With sleek, minimalist lines and a matte finish, PU-T01 Countertop Water Purifier exudes premium texture at just a glance. Place it in your kitchen, living room, or even study—it instantly enhance the style of your room. It’s not just an appliance, it’s a modern lifestyle statement.

Compact & Space-Saving: Slightly larger than an A4 sheet of paper, this water purifier fits easily even on small countertop. Need to move it? The no installation design also makes it easy to move and place wherever needed.

Adds a Touch of Ritual to Life: Imagine using your countertop water filter to start your day with a refreshing cup of warm water in the morning. Then, in the afternoon, press the 85°C button to brew a cup of tea for friends. This countertop water purifier brings you convenience and elegance. This readily available high-quality drinking water experience is itself an attitude towards refined living.

Pure Taste, Elevated Experience!

Convenience and beauty may catch your eye, but the core of it all is pure, healthy drinking water.

Powerful Filtration: Using multi-stage filtration (PP cotton, activated carbon, and RO system), this countertop water purifier effectively removes chlorine, odors, and more—delivering water that’s truly safe to drink.

Upgraded taste: The difference is immediate—water tastes sweet and clean. PU-T01 Countertop RO Water Purifier can bring you a taste with naturally crisp, refreshing, and silky-smooth. Tea becomes more fragrant, coffee more layered—water quality truly makes the difference.

Every Sip, Peace of Mind: Perfect for families with children or elderly members—Its RO system guarantees safe, clean hot or warm water at all times. No more worrying, just effortless daily hydration.

The Perfect Blend of “Lazy & Refined” Living

The PU-T01 Countertop Water Purifier is more than just a tool for drinking water. It’s a lifestyle companion that perfectly balances effortless convenience with quality.

It transforms the simplest act—drinking water—into something lighter, smoother, and more graceful than ever.

It frees you from hassle, and instead makes you enjoy the process of drinking water.

It quietly yet steadily elevates your daily comfort and sense of quality.

If you’ve ever:

Felt tired of boiling, waiting, and carrying heavy water bottles…

Wanted cleaner, fresher water with a better taste…

Valued the design and aesthetics of home appliances…

Looked for modern solutions that save time and simplify life…

Then this purifier—especially the PU-T01 countertop water purifier—might just be the missing piece of your “lazy-yet-refined” lifestyle puzzle.

No complicated installation. Just plug it in, fill the tank, and enjoy. Its compact design fits seamlessly into any space—kitchen, living room, even your work desk—blending in like a stylish decoration piece. This hot and cold water dispenser brings crystal-clear water at just the right temperature, thanks to its smart heating options. These thoughtful details make life not only healthier, but calmer and more enjoyable.

In short, this stylish and ultra-convenient countertop water filter is one of the best investments you can make to boost your home happiness this year. Because at the end of the day, drinking well is the very first step to living well.