Choosing the right warehouse racking system can make or break your storage efficiency and operational costs. Whether you're expanding your current warehouse or designing a new facility, understanding the differences between drive-in racks, shuttle racking, and mobile racking is crucial for maximizing your investment.

What is Drive-In Racking?

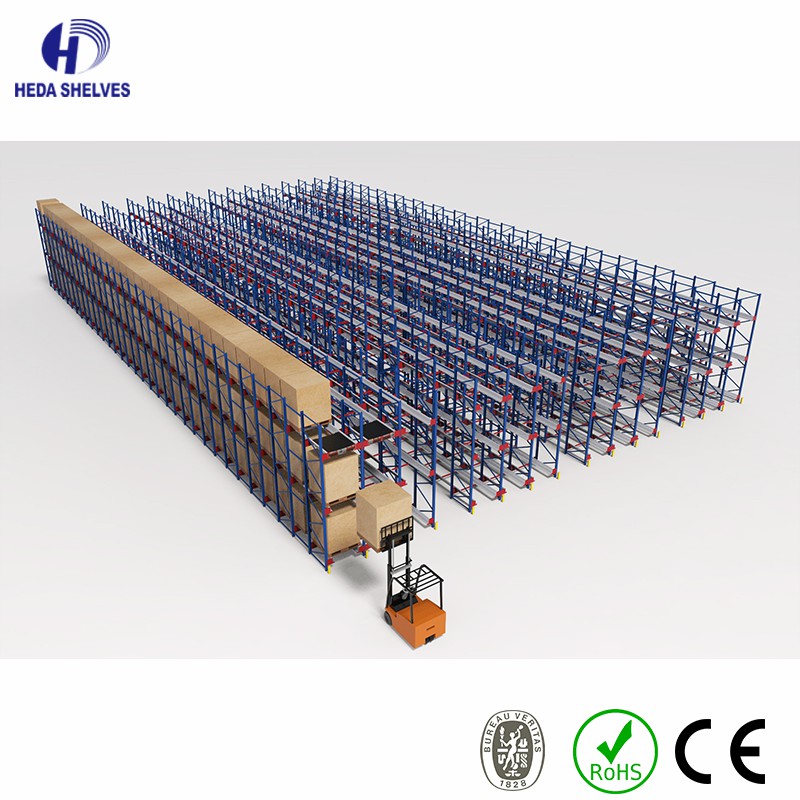

Drive-in racking is a high-density storage system that allows forklifts to drive directly into the rack structure to store and retrieve pallets. This system operates on a Last-In-First-Out (LIFO) principle, making it ideal for storing large quantities of similar products with longer storage periods.

How Drive-In Racking Works

The system consists of continuous rails that support pallets at multiple levels. Forklifts enter the rack structure through entry points and travel along guide rails to place or retrieve pallets. The structural framework includes uprights, rails, and bracing that create drive lanes typically 10-12 feet wide.

Drive-in racks can be configured as either drive-in (single entry point) or drive-through (entry and exit points at opposite ends) depending on your operational requirements. The LIFO system means the last pallet stored is the first one retrieved, which works perfectly for products with longer shelf lives or seasonal inventory.

Key Features:

- LIFO system (Last In, First Out)

- Eliminates aisles between racks

- Reduces pick faces by up to 75%

- Cost-effective for high-volume, low-SKU operations

- Requires specialized forklift training

What is Mobile Racking?

Mobile racking systems mount entire rack structures on motorized bases that move along rails. These systems eliminate fixed aisles by creating a single working aisle that moves between rack rows as needed.

How Mobile Racking Works

The system operates through electric motors, mechanical hand wheels, or hydraulic systems that move entire rack sections along rails embedded in the warehouse floor. When access is needed to specific products, the relevant racks separate to create a working aisle exactly where it's required.

Mobile racking systems can be configured with various control options, from simple mechanical systems to sophisticated computerized controls with safety sensors and automatic positioning.

Key Features:

- Highest space utilization – up to 95% floor usage

- Maintains 100% pallet selectivity

- Reduces building footprint requirements

- Energy-efficient motor systems

- Ideal for slow-moving inventory

What is Shuttle Racking?

Shuttle racking represents the evolution of high-density storage into the semi-automated realm. This system combines the space efficiency of drive-in racking with radio-controlled shuttle cars that move pallets within the rack structure, eliminating the need for forklifts to enter the racking system.

How Shuttle Racking Operates

The shuttle system uses battery-powered carts that run on rails within each storage level. These shuttles are controlled via radio frequency and can move pallets deep into the rack structure. Forklifts only need to place pallets at the face of the rack and position the shuttle car at the appropriate level.

The shuttle car receives commands through a remote control or warehouse management system integration. It can operate in both FIFO (First-In-First-Out) and LIFO modes, providing flexibility that traditional drive-in racks cannot offer.

Key Features:

- Semi-automated operation with remote control

- FIFO (First In, First Out) or LIFO capability

- Faster throughput than drive-in systems

- Reduced product damage and forklift wear

- Scalable automation levels

Key Difference for these racking system

| Feature | Drive-In Racking | Shuttle Racking | Mobile Racking |

| Storage Density | High (60-75% floor usage) | High (65-80% floor usage) | Highest (85-95% floor usage) |

| Selectivity | Limited (LIFO only) | Good (FIFO/LIFO options) | Excellent (100% selectivity) |

| Operating Speed | Moderate | Fast | Slow to moderate |

| Investment Cost | Lowest | Moderate to high | Highest |

| Maintenance | Minimal | Regular (shuttle carts) | Moderate (motors/rails) |

| Product Damage Risk | Higher | Lower | Lowest |

| Automation Potential | None | High | Moderate |

How to Choose the Right Dynamic Racking System

After two decades in this industry, I've developed a proven framework for making this critical decision:

1. Analyze Your Inventory Profile

High-volume, few SKUs: Drive-in racking excels

Medium variety, fast turnover: Shuttle racking wins

High variety, slow turnover: Mobile racking dominates

2. Evaluate Your Throughput Requirements

Low to moderate throughput: Drive-in works perfectly

High throughput needs: Shuttle racking delivers speed

Selective access priority: Mobile racking ensures 100% accessibility

3. Consider Your Budget Reality

Budget-conscious operations should start with drive-in racking. Growing businesses with increasing throughput demands benefit from shuttle systems. Premium operations requiring maximum space efficiency justify mobile racking investments.

4. Assess Your Labor Situation

Experienced forklift operators: Drive-in systems work well

Labor shortage concerns: Shuttle racking reduces operator dependency

Minimal daily activity: Mobile racking handles low-frequency access efficiently

Practical Examples

Case Study 1: Cold Storage Facility

A frozen food distributor with limited SKUs but massive volumes chose drive-in racking. Result: 40% increase in storage capacity with minimal investment. The LIFO system worked perfectly for their product rotation needs.

Case Study 2: E-commerce Fulfillment Center

An online retailer with 200+ SKUs and daily picking requirements implemented shuttle racking. Outcome: 60% faster throughput and 30% reduction in product damage compared to their previous drive-in system.

Case Study 3: Pharmaceutical Warehouse

A pharmaceutical company with strict FIFO requirements and premium real estate costs chose mobile racking. Achievement: 90% floor utilization while maintaining complete lot traceability and access to every pallet.

Making Your Final Decision

The best racking system isn't always the most expensive or technologically advanced – it's the one that perfectly matches your operational needs. Here's my expert recommendation process:

Start with drive-in racking if you're dealing with high-volume, low-variety inventory and have budget constraints. It's the proven workhorse of high-density storage.

Upgrade to shuttle racking when throughput becomes your bottleneck and you need faster, safer operations. The automation capabilities make it future-ready for growing businesses.

Invest in mobile racking when space is your most expensive resource and you need maximum flexibility with complete selectivity.

Conclusion

After 20 years of helping businesses optimize their warehouse operations, I can confidently say there's no universal best choice – only the best choice for your specific situation. Drive-in racking offers unbeatable value for simple, high-volume storage. Shuttle racking delivers the perfect balance of density, speed, and automation. Mobile racking provides ultimate flexibility for complex inventory management needs.

If you plan on set up a warehouse for new business like retail, wholesale,logistic and more, choose a trustworthy racking system manufacturer is essential. Heda Shelves is leading warehouse racking system factory in China since 2001. We Offer OEM&ODM Service for your storage needs in factory price. Contact us Today.

FAQ

Q: Can I mix different racking systems in the same warehouse?

A: Absolutely! Many of my clients use hybrid approaches – drive-in for fast-moving bulk items, mobile for slow-movers, and shuttle for medium-velocity products.

Q: Do I need special forklifts for these systems?

A: Drive-in requires reach trucks or specialized narrow-aisle forklifts. Shuttle and mobile systems work with standard counterbalance forklifts.

Q: How do I handle maintenance for automated systems?

A: Shuttle systems require scheduled maintenance contracts with manufacturers. Mobile systems need regular rail cleaning and motor servicing, typically manageable in-house.