Today, water safety has become a growing concern, and many households are choosing to install under sink RO water filtration systems. Quietly tucked away in your kitchen cabinet, these systems take up very little counter space while providing clean drinking water for the whole family.

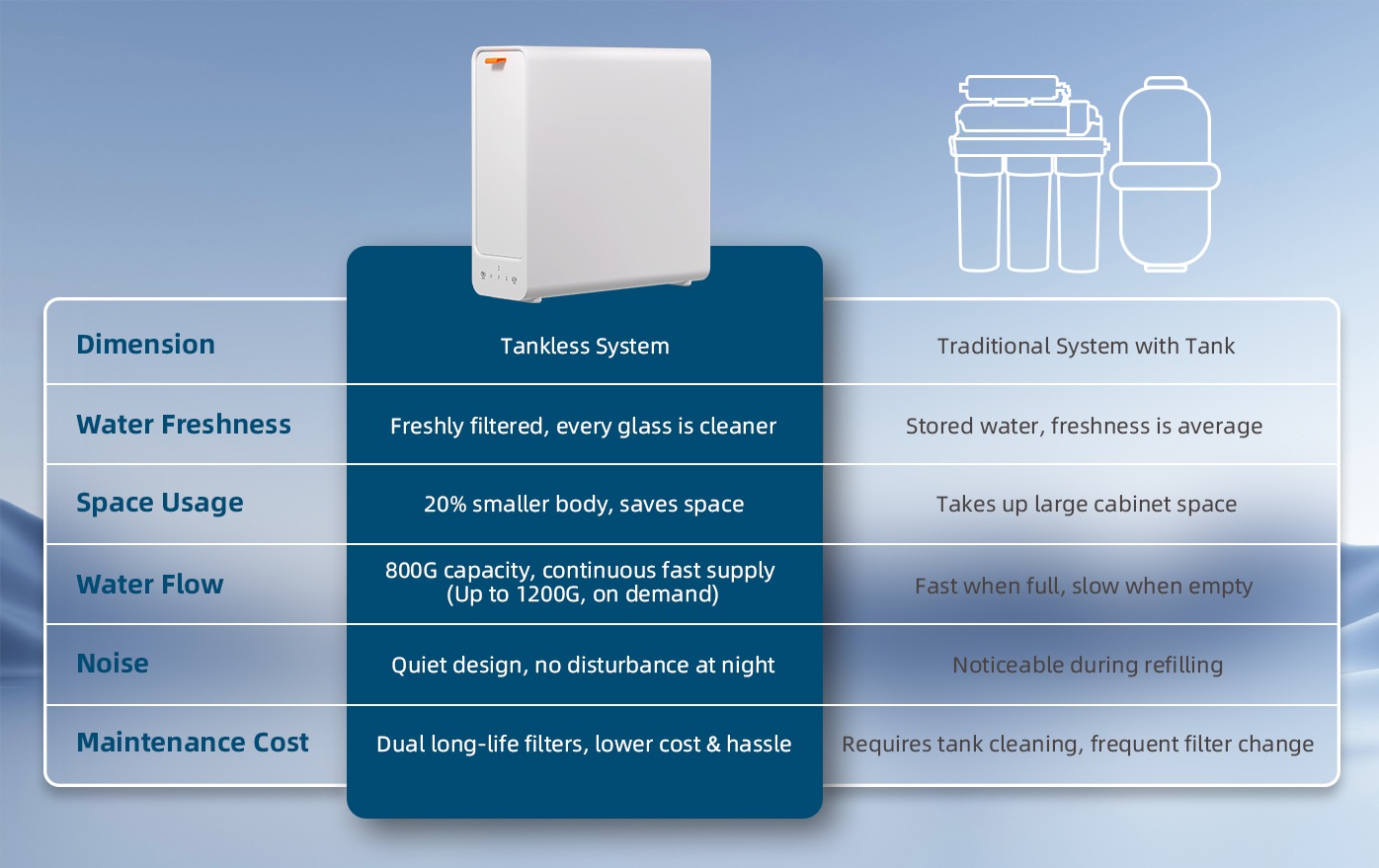

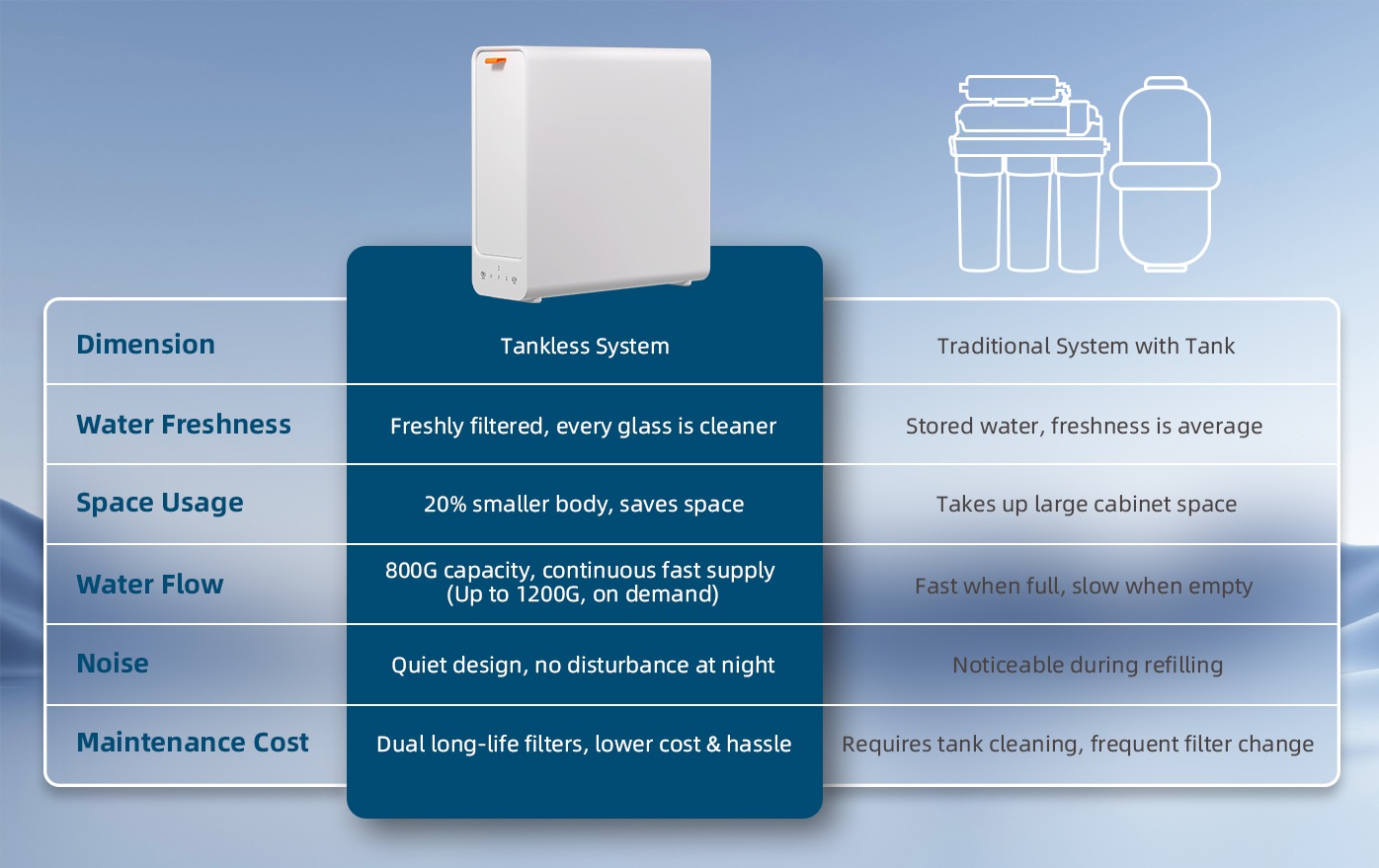

But when it comes to choosing the right model, one common dilemma arises: tank or tankless? The difference is not just about design—it’s closely tied to your daily water use.

Let’s compare the two options across a few key dimensions to see which one is the best fit for your kitchen.

Water Quality & Freshness

-Traditional System with Tank:

A tank-based RO filtration system stores purified water in a reservoir, ready whenever you need it. The benefit is instant water flow without waiting, but the downside is potential secondary contamination if water sits too long in the tank. Especially in summer, stored water may taste a little “stale.”

-Tankless System:

A tankless system delivers water on demand. Every glass passes directly through the high-capacity RO membrane before it reaches your cup—fresher, cleaner, and safer. You don’t have to worry about hidden risks from long-term storage.

Imagine coming home late from work and pouring a glass of water. With a traditional system with tank, that water might have been sitting in the tank all day. With a tankless system, it’s freshly filtered the moment you turn on the tap. Which one would you prefer?

Space Efficiency

-Traditional System with Tank:

The water tank often takes up a large portion of your cabinet. For smaller kitchens or apartments, this can mean sacrificing valuable storage space—you may only fit the system, leaving little room for cookware or other items.

-Tankless System:

Without a bulky tank, the unit is far more compact and space-saving. For example, the PU-C01 under sink RO water filtration system is about 20% smaller than standard models. Install it under your sink, and suddenly you’ll have more room left over for a rice cooker or even a case of drinks.

You’re cooking and want to grab something from the cabinet, only to find the tank blocking your way. You end up moving it aside just to reach your pot. With a tankless system, that hassle disappears—the slim design fits seamlessly without wasting space.

Water Flow & Efficiency

-Traditional System with Tank:

When the tank is full, water comes out quickly. Once the water in the tank is depleted, the water purification efficiency and flow rate will significantly decrease. During peak times, like a big family dinner, it often can’t keep up with demand.

-Tankless System:

Equipped with a high-capacity reverse osmosis membrane, tankless models deliver a stable, continuous flow. Take the PU-C01 under sink RO water filtration system as an example: its dual-filter design and 800G capacity (Up to 1200G, on demand) provide up to 2.1L/min flow rate—more than enough for multiple uses at once, whether it’s boiling soup, brewing tea, or making coffee.

Guests come over, and you need water for a big pot of soup, plus tea, coffee, and daily use—all at the same time. For tank-based systems, the water flow rate from the storage tank will gradually decrease as the water level drops, potentially leading to insufficient water supply during peak usage. In contrast, the PU-C01 under sink RO water filtration system’s 800G flow (Up to 1200G, on demand) delivers nonstop clean water without interrupting the dinner party.

Noise Levels

-Traditional System with Tank:

Because of the pressurizing and refilling process, traditional systems with tank often generate noticeable noise while in use. If your kitchen is close to the bedroom, nighttime water use could disturb family members’ sleep.

-Tankless System:

Modern tankless models are designed with quieter operation in mind. The tankless water filtraion system is significantly quieter than tank-based systems. Even when you draw water late at night, the sound of operation is barely noticeable.

You wake up thirsty at midnight and quietly head to the kitchen for a glass of water. With a traditional system with tank, the pump noise could wake your family. With a tankless system, water flows silently, keeping everyone’s rest undisturbed.

Maintenance & Long-Term Costs

-Traditional System with Tank:

The storage tank requires regular cleaning to prevent bacterial growth, and filters often need to be replaced more frequently—leading to higher maintenance costs over time.

-Tankless System:

With no storage tank, there’s no risk of bacteria breeding in stagnant water and no need for tank cleaning. The PU-C01 system features a dual-filter setup with long-lasting cartridges, reducing replacement frequency and saving costs in the long run.

With a tank-based system, you’ll need to arrange periodic professional cleaning of the water tank—costing both time and money. A tankless under sink RO water filtration system eliminates this hassle, protecting your family’s drinking water health with far less effort.

From the comparison, it’s clear that traditional systems with tank offer the advantage of lower upfront cost, while tankless RO systems better meet modern households’ needs for freshness, efficiency, space-saving, and convenience—with more obvious advantages overall.

PU-C01 Under-Sink RO Water Filtration System: A Quiet Yet Smart Choice

If tankless systems represent the future trend, the PU-C01 under sink RO water filtration system turns that trend into reality in everyday life:

•800G High Capacity: Fast, uninterrupted water flow for continuous use.

•Tankless Design: No bulky reservoir, lighter weight, saves cabinet space—even small apartments can install it with ease.

•Dual Long-Life Filters: Designed to last, reducing replacement frequency and making maintenance simpler.

•Dual Outlet System: Separate water lines for drinking and cooking, cleaner and more flexible.

•RO Membrane Filtration: Deep purification for crisp, clean, refreshing water.

Most importantly, the PU-C01 under sink RO water filtration system is more affordable than you might expect. Unlike many high-end models, it balances strong performance with budget-friendly pricing—making it a practical, cost-effective choice.

Which One Should You Choose?

If budget is your top priority, you don’t mind sacrificing cabinet space, and you’re willing to spend the time and effort regularly cleaning the storage tank, then a RO system with tank can still serve your needs.

But if you value a cleaner kitchen layout, fresher drinking water, higher flow efficiency, and hassle-free maintenance, then a tankless under sink RO system is clearly the better choice.

Among tankless options, the PU-C01 under sink RO water filtration system stands out for its compact size, convenience, clean performance, and durability. It may not be the flashiest appliance in your kitchen, but it quietly provides the pure water that modern family life depends on.